Egg

Buyer's Guide

United States Eggs

Distinguished Quality

Egg production in the U.S. comprises a vital segment of the agricultural landscape. America’s Egg Farmers manage more than 300 million table egg type hens, and each hen lays nearly 300 eggs every year.

Approximately seventy percent of all table eggs produced in the U.S. are marketed as shell eggs for home, institutional, and food service operations worldwide.

Egg production in the U.S. comprises a vital segment of the agricultural landscape. America’s Egg Farmers manage more than 300 million table egg type hens, and each hen lays nearly 300 eggs every year.

Approximately seventy percent of all table eggs produced in the U.S. are marketed as shell eggs for home, institutional, and food service operations worldwide.

The U.S. produces the highest quality eggs and egg products in the world.

The U.S. is the second largest global egg producer, and the American egg industry maintains strict quality control and sanitation measures more stringent than what is required by law.

U.S. eggs are washed and sanitized immediately after they are laid. The U.S. Department of Agriculture then grades the eggs before they are packed. Once packed, the eggs are refrigerated, and their temperature is controlled throughout the shipping and marketing process.

The U.S. produces the highest quality eggs and egg products in the world.

The U.S. is the second largest global egg producer, and the American egg industry maintains strict quality control and sanitation measures more stringent than what is required by law.

U.S. eggs are washed and sanitized immediately after they are laid. The U.S. Department of Agriculture then grades the eggs before they are packed. Once packed, the eggs are refrigerated, and their temperature is controlled throughout the shipping and marketing process.

U.S. eggs are shipped around the world. From Iowa to Hong Kong, Mexico, Japan, and beyond, buyers prefer U.S. eggs and egg products for their high quality and nutritional benefits.

U.S. eggs are shipped around the world. From Iowa to Hong Kong, Mexico, Japan, and beyond, buyers prefer U.S. eggs and egg products for their high quality and nutritional benefits.

There are numerous benefits of eating eggs for people of all ages and life stages. Eggs are an excellent source of:

- High quality protein

- Vitamin B12

- Biotin (B7)

- Iodine

- Selenium

- Choline

- Riboflavin (B2)

- Pantothenic Acid (B5)

Studies have also proven eggs contain important antioxidants. Lutein and zeaxanthin in eggs may reduce the risk of age-related macular degeneration and cataracts. Pregnant mothers may also benefit from eating eggs. The choline found in eggs can have lasting beneficial effects on brain health and development for babies into their school-age years. Amazingly, each egg offers all these health benefits with only 70 calories. Eggs are a nutritional powerhouse that contribute to a healthy, balanced diet for everyone.

There are numerous benefits of eating eggs for people of all ages and life stages. Eggs are an excellent source of:

- High quality protein

- Vitamin B12

- Biotin (B7)

- Iodine

- Selenium

- Choline

- Riboflavin (B2)

- Pantothenic Acid (B5)

Studies have also proven eggs contain important antioxidants. Amazingly, each egg offers all these health benefits with only 70 calories.

Quality Inspection

Maintaining high quality standards is an American egg producer’s top priority. The process begins before the egg is laid to the moment it reaches the consumer.

When eggs enter the processing facility, they are immediately washed with detergent sanitizing solution. This process removes dirt without damaging the shells or altering the quality. After washing, eggs are rinsed, sanitized, USDA graded, and packed. Next, the eggs are candled, which is the process of using light to determine the egg’s quality. Finally, they are immediately moved to cooling facilities where they’re readied for distribution.

Maintaining high quality standards is an American egg producer’s top priority. When eggs enter the processing facility, they are immediately washed with detergent sanitizing solution. This process removes dirt without damaging the shells or altering the quality. After washing, eggs are rinsed, sanitized, USDA graded, and packed.

U.S. eggs are washed, sanitized, packed, and shipped within hours of laying. To maximize safety and quality, eggs are refrigerated throughout the supply chain and transportation process. Eggs are shipped either by refrigerated trucks or aboard ocean vessels in refrigerated containers set at 38°F (3.36°C).

Road weight restrictions in the U.S. limit the number of cases that can be shipped in a container or trailer truck.

U.S. eggs are washed, sanitized, packed, and shipped within hours of laying. Eggs are refrigerated throughout the supply chain and transportation process. Eggs are shipped by refrigerated trucks or aboard ocean vessels in refrigerated containers set at 38°F (3.36°C). Road weight restrictions in the U.S. limit the number of cases that can be shipped in a container or trailer truck.

United States Department of Agriculture (USDA) standards classify U.S. shell eggs into one of three consumer grades based on the interior and exterior quality of the egg.

- Grade AA eggs are the freshest and highest quality. When broken, the egg yolk and white stay compact and cover a small area. The white is firm and thick, while the yolk is round and stands up.

- Grade A eggs are very high quality. The yolk and white spread a small amount when broken. The whites are thinner but remain firm. The yolk is round and not as tall as a Grade AA egg.

- Grade B eggs are usually used for breaking stock (liquid eggs) rather than sold at retail. Most Grade B eggs are sold to bakeries and institutions and are excellent for hard boiling.

Note that USDA egg grades are not an indication of nutritional value. USDA egg grading occurs according to U.S. government regulations at the time the egg is packed.

USDA standards classify U.S. shell eggs into one of three consumer grades:

- Grade AA eggs are the freshest and highest quality.

- Grade A eggs are very high quality.

- Grade B eggs are usually used for breaking stock (liquid eggs).

The USDA Agricultural Marketing Service (AMS) is responsible for the Shell Egg Surveillance Program to assure that eggs in the marketplace are as good as or better than U.S. Consumer Grade B quality standards. AMS conducts inspection of handlers and hatcheries four times each year to ensure conformance with these requirements. Eggs exceeding the tolerance for checks or loss must be diverted from the marketplace for further segregation or processing. The USDA grade mark on egg cartons means the plant processed the eggs following USDA’s sanitation and good manufacturing processes.

The USDA Animal and Plant Health Inspection Service (APHIS) conducts activities to reduce the risk of disease in flocks of laying hens. APHIS administers the voluntary National Poultry Improvement Plan (NPIP), which certifies that poultry breeding stock and hatcheries are free from certain diseases. Participation is necessary for producers that ship interstate or internationally.

The USDA Food Safety and Inspection Service (FSIS) is responsible for the import of eggs destined for further processing and for assuring that imported shell eggs destined for the retail market are transported under refrigerated conditions. FSIS verifies shell eggs packed for the consumer are labeled “Keep Refrigerated” and stored and transported under refrigeration and ambient temperature of no greater than 45 °F.

The USDA Agricultural Marketing Service (AMS) is responsible for the Shell Egg Surveillance Program to assure consumer eggs are as good as or better than Grade B quality standards. The USDA Food Safety and Inspection Service (FSIS) verifies shell eggs packed for the consumer are labeled “Keep Refrigerated” and stored/ transported under refrigeration at a temperature of no greater than 45 °F.

The United States Food and Drug Administration enforces regulation expected to prevent approximately 79,000 cases of foodborne illness and 30 deaths each year caused by the consumption of eggs contaminated with the bacterium Salmonella Enteritidis.

The regulation requires producers to take preventive measures during the production of eggs in poultry houses, and it requires subsequent refrigeration during storage and transportation. The measures are designed to prevent Salmonella Enteritidis be adopted by virtually all egg farmers with 3,000 or more laying hens whose shell eggs are not processed with a treatment, such as pasteurization, to ensure their safety.

The FDA enforces regulation to prevent approximately 79,000 cases of foodborne illness and 30 deaths each year caused by the consumption of eggs contaminated with the bacterium Salmonella Enteritidis. The regulation requires producers to take preventive measures during the production of eggs in poultry houses, and requires subsequent refrigeration during storage and transportation.

Shell Eggs

Many people assume brown eggs are healthier than white eggs. This is not true. All eggs start out white, but brown eggs receive additional pigment in the final stage of shell development. The same principle applies to egg yolk color. There are no discernable differences in taste, nutrition, or quality between pale yellow egg yolks and rich orange yolks.

What determines the egg shell and yolk color is actually the breed of chicken. Different breeds require different care, though. Hens that lay brown eggs or eggs with different yolk colors require more feed to lay eggs, so their eggs can be more expensive.

Regardless of egg shell and yolk color, all large eggs contain 6 grams of protein and only 70 calories.

Many people assume brown eggs are healthier than white eggs. This is not true. All eggs start out white, but brown eggs receive additional pigment in the final stage of shell development. The same principle applies to egg yolk color. There are no discernable differences in taste, nutrition, or quality between pale yellow egg yolks and rich orange yolks.

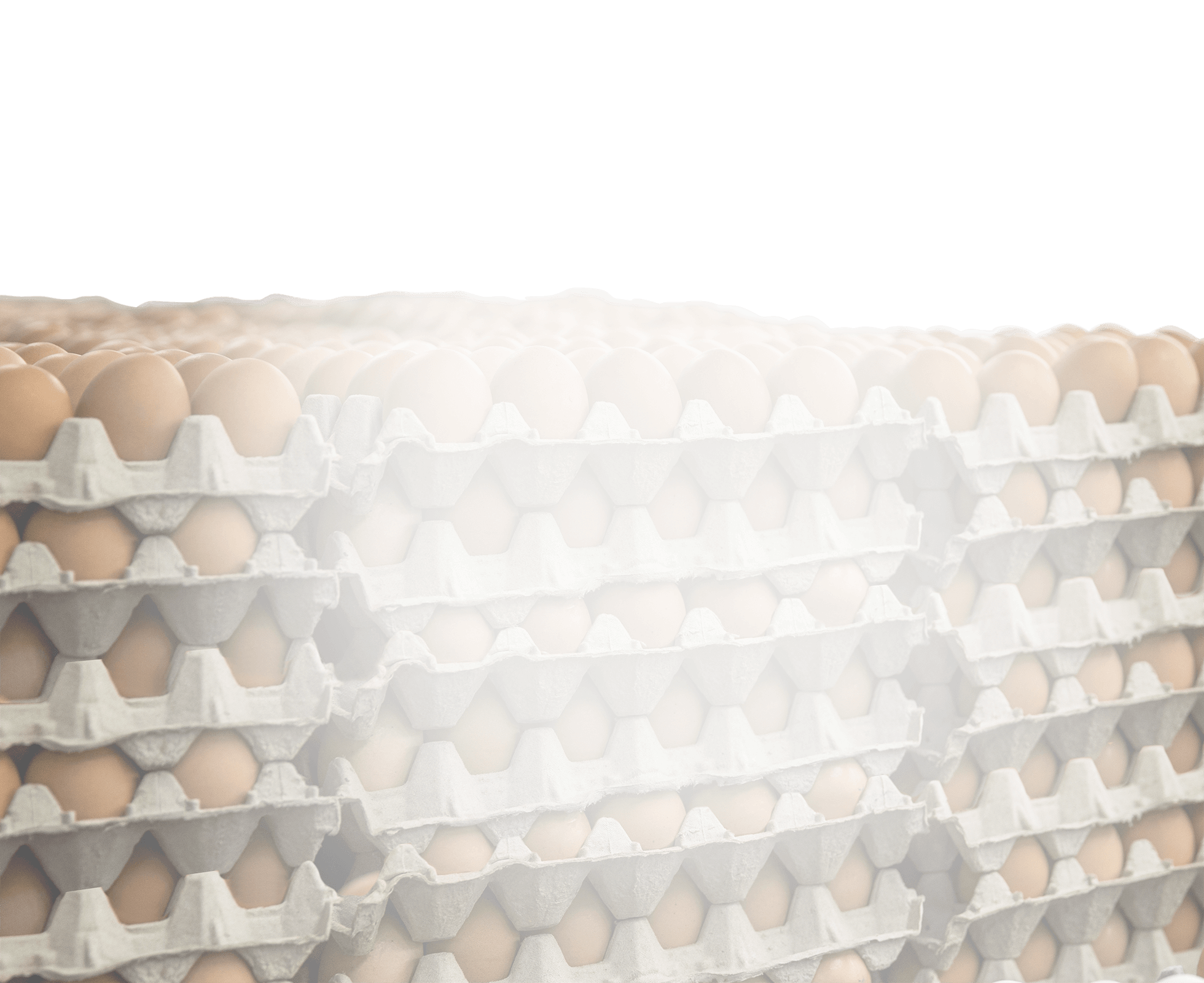

Shell eggs are primarily packaged and transported on plastic or fiber flats that hold 30 eggs. Filled trays are then packed into cases that hold 360 eggs. For storage and transport, a 30 dozen case size capacity is standard throughout the industry.

A typical retail carton package is formed from pulp or foam and is designed to hold 12 shell eggs. The carton controls breakage and prevents the loss of moisture and carbon dioxide, which helps keep eggs fresh. According to mandatory federal labeling requirements, each carton must include the name and address of the packer or distributor, the net contents, identity of the product, nutritional labeling, and safe handling instructions. Each egg carton with the USDA grade shield must also display the pack date, also known as the Julian date, which is the day that the eggs were washed, graded, and placed in the carton. The pack date is formatted as a three-digit code that represents the consecutive day of the year, starting with January 1 as 001 and ending with December 31 as 365.

Shell eggs are primarily packaged and transported on plastic or fiber flats that hold 30 eggs. Filled trays are then packed into cases that hold 360 eggs. For storage and transport, a 30 dozen case size capacity is standard throughout the industry.

Shell egg farms are more sustainable than ever due to increased feed efficiency, advancements in hen housing, and manure management. Egg farms today use less water and energy daily and release lower amounts of polluting emissions than farms of the past.

Every aspect of the egg production process, including cultivating feed and raising the laying hens, has been updated to reduce the industry’s environmental footprint and incorporate sustainability practices. A landmark Egg Industry Center study compared U.S. egg production in 2010 to the industry in 1960. The egg sustainability study showed that while production has increased over the past 50 years, the industry significantly decreased its environmental footprint. According to the study, it takes 32 percent less water to produce a dozen eggs than it did in 1960. The volume of water that the U.S. egg production industry conserved from 1960 to 2010 would fill 3,716 Olympic sized swimming pools.

Shell egg farms are more sustainable than ever due to increased feed efficiency, advancements in hen housing, and manure management. Egg farms today use less water and energy daily and release lower amounts of polluting emissions than ever. Every aspect of the egg production process has been updated to reduce the industry’s environmental footprint.

U.S. shell eggs are refrigerated to conserve moisture longer, which promotes quality and safety. This means that refrigerated eggs have a longer shelf life.

At room temperature, an egg deteriorates more overnight than it does over one week in the refrigerator. Research also shows refrigeration maintains the shelf life of USDA Grade AA eggs for a minimum of 15 weeks.

For eggs, refrigerator temperatures should be kept at 39.2°F (4°C).

U.S. shell eggs are refrigerated to conserve moisture longer, which promotes quality and safety. This means that refrigerated eggs have a longer shelf life. At room temperature, an egg deteriorates more overnight than it does over one week in the refrigerator. For eggs, refrigerator temperatures should be kept at 39.2°F (4°C).

Processed Egg Products

Food manufacturers and foodservice operators appreciate processed egg products because they are convenient, high quality, and require less labor. They are also easy to store, stable, and uniform, which allows operators to easily control portion sizes. Lastly, processed egg products are simpler to manage from a food safety and hygiene perspective.

Food manufacturers and foodservice operators appreciate processed egg products because they are convenient, high quality, and require less labor. They are also easy to store, stable, and uniform, which allows operators to easily control portion sizes. Lastly, processed egg products are simpler to manage from a food safety and hygiene perspective.

Liquid egg products are pasteurized for optimal food safety and hygiene. Liquid pasteurized egg products are also quick and easy to cook.

- Whole liquid eggs, yolks, and whites

- Salted whole eggs and yolks

- Liquid scrambled egg mix

- Liquid sugar egg yolks

- Enzyme modified liquid products

- Extended shell life whole eggs, whites, yolks, and scrambled egg mix

Liquid egg products are pasteurized for optimal food safety and hygiene, and are quick and easy to cook. Products include whole liquid eggs, yolks, and whites; salted whole eggs and yolks; liquid scrambled egg mix; liquid sugar egg yolks; enzyme modified liquid products; extended shell life whole eggs, whites, yolks, and scrambled egg mix.

Dried egg products are stable, easy to mix, and have a long shelf life. Food safety and hygiene are also easily maintained with dried egg products.

- Whole dried eggs and egg yolk solids

- Dried egg and scrambled egg mix

- Dried egg whites

- Instant, spray dried, pan dried, high whip and high gel

- Free flowing whole eggs and egg yolk solids

- Stabilized (glucose free) whole eggs and egg yolk solids

- Blends of whole eggs or yolk with carbohydrates

- Enzyme modified dried products

Dried egg products have a long shelf life. Food safety & hygiene are also easily maintained. Products include whole dried eggs & yolk solids; dried & scrambled egg mix; dried egg whites; instant, spray dried, pan dried, high whip & high gel; free flowing products; stabilized (glucose free) products; blends of whole eggs or yolk with carbohydrates; enzyme modified.

Frozen egg products have a variety of functions and blends. They also have a long shelf life and are safe and hygienic.

- Frozen scrambled egg mix

- Frozen salted whole eggs and egg yolks

- Frozen sugar egg yolks

- Whole egg yolks with corn syrup

- Whole eggs with citric acid or corn syrup

- Whole frozen eggs, whites, and yolks

- Enzyme modified frozen products

Frozen egg products have a variety of functions & blends. They also have a long shelf life & are safe & hygienic. Products include frozen scrambled egg mix; salted whole eggs & yolks; sugar egg yolks; whole yolks with corn syrup; whole eggs with citric acid or corn syrup; whole frozen eggs, whites, & yolks; enzyme modified frozen products.

Egg products are processed in sanitary facilities under constant USDA supervision. The first step in making egg products is breaking the eggs. The yolks, whites, and shells are then separated. Sophisticated egg breaking equipment can break as many as 144,000 eggs per hour, which is equivalent to 400 thirty-dozen cases, or 40 eggs per second.

Each separated white and yolk are examined by the machine operator. Eggs that do not meet the operator’s standards are not processed for human consumption.

Egg products are processed in sanitary facilities under constant USDA supervision. The first step is breaking the eggs, then the yolks, whites, and shells are separated. Sophisticated equipment can break up to 144,000 eggs per hour, which is equivalent to 400 thirty-dozen cases. Each separated white and yolk are examined by the machine operator.

After the egg is broken, the liquid product is filtered, mixed, and chilled before undergoing additional processing. Finally, the egg product is pasteurized, which is required by law. During pasteurization, the egg is rapidly heated to reduce the risk of food-borne illnesses. Pasteurization does not cook the egg, and the process has no negative effect on the color, flavor, nutritional value, or use of the egg.

After the egg is broken, the liquid product is filtered, mixed, and chilled. Finally, the product is pasteurized, which is required by law. During pasteurization, the egg is rapidly heated to reduce risk of food-borne illness. Pasteurization does not cook the egg, and the process has no negative effect on color, flavor, or nutritional value.

The Egg Products Inspection Regulations (EPIR) mandates that eggs undergo the same level of scrutiny as meat and poultry products. Under EPIR, federally inspected egg products plants are required to develop and implement Hazard Analysis and Critical Control Points (HACCP) systems and Sanitation Standard Operating Procedures (SSOPs).

The Food Safety and Inspection Service (FSIS) tests facilities for Salmonella and Listeria monocytogenes (Lm). FSIS requires that plants produce egg products that meet food safety standards and are edible without additional preparation. In addition, FSIS assumes regulatory authority over egg substitutes and freeze-dried egg products. These products carry the same risks as other egg products and are inspected in the same manner.

The Egg Products Inspection Regulations (EPIR) mandate that eggs undergo the same precautions as other meat products. Plants must develop & implement Hazard Analysis & Critical Control Points (HACCP) systems & Sanitation Standard Operating Procedures (SSOPs). The Food Safety & Inspection Service (FSIS) tests facilities for Salmonella & Listeria monocytogenes.

Whole Egg Uses

- Frozen or dried whole eggs are used by bakeries in doughs, pie bases and fillings.

- Frozen salted whole eggs may be used in baby foods.

- Dried whole eggs with or without free flow are used in noodles.

- Frozen whole eggs with citric acid are utilized by the foodservice industry and in scrambled egg buffet services.

Egg White Uses

- Standard frozen or dried egg whites are useful for pie fillings, baby foods, and noodles.

- High whip (angel) frozen or dried egg whites are used by bakeries in pie toppings, confections, nougat, and angel food cake.

- Dried high gel egg whites are excellent for surimi, composite meats, and snack bars.

Egg Yolk Uses

- Frozen or dried egg yolks may be used in mayonnaise, salad dressings, savory sauces, noodles, baby foods, doughs, and in foodservice and bakery applications.

- Frozen salted egg yolks (10% salt) are used in mayonnaise, salad dressings, and sauces.

- Frozen sugared egg yolks (10% sugar) are excellent for custards, flan, sweet sauces, doughs, and are often used by bakeries.

- Frozen or dried enzyme modified egg yolks are an ingredient in mayonnaise, salad dressings, and sauces.

Whole eggs are used in doughs, pie bases, fillings, and buffets. Egg whites are useful for pie fillings, baby foods, and noodles. Bakeries use high whip whites in confections, nougat, and angel food cake. High gel whites are excellent for surimi and snack bars. Egg yolks may be used in sauces, custards, flan, and foodservice and bakery applications.

Store liquid processed egg products according to the processor's recommendations. Most products should be used within six days. Extended shelf life products may last longer (again, follow the supplier’s recommendations).

Use pallets for dried egg products and keep them in dry storage away from extreme temperatures and strong odors. Keep frozen processed egg products below 10°F (-12°C). Thaw in the refrigerator or set them in cold running water. Use frozen egg products as soon as possible after thawing. Dried and frozen products have a one year shelf life (before opening).

Store liquid products according to the processor's recommendations. Most products should be used within six days. Extended shelf life products last longer. Keep dried products on pallets in dry storage away from extreme temperatures. Keep frozen products below 10°F (-12°C). Thaw in refrigerator or cold running water, and use as soon as possible after thawing.

.jpg)

.jpg)

Value-Added Egg Products

There’s a wide variety of value added egg products. Each type offers different advantages.

All cooked egg products are food safe, consistent in taste and appearance, and are designed to reduce labor. Cooked egg products ensure value and customer satisfaction. Simply heat and serve.

Cooked Egg Products

- Hard cooked eggs, dry and brine pack

- Diced egg

- Pre-cooked scrambled egg

- Egg patties, quiches, omelets, and French toast

All cooked egg products are food safe, consistent in taste and appearance, and designed to reduce labor. Cooked egg products ensure value and customer satisfaction. Simply heat and serve. Products include hard cooked, dry & brine pack; diced; pre-cooked scrambled egg; patties, quiches, omelets, & French toast.

The Processed Eggs and Egg Products Export Verification (PEEPEV) Program helps manage regulation compliance verification audits. Program management issues export certificates and helps protect consumers by ensuring the egg industry meets FDA Good Manufacturing Practices (GMPs) requirements.

The program requires producers to verify (every 6 months) that products:

- Produced for export are certified fit for human consumption in accordance with the FDA’s current Good Manufacturing Practices (GMPs);

- Were produced in accordance with management’s conformity to AMS’ Quality System Assessment (QSA) Program Requirements; and

- Meet public health attestations of the respective foreign government.

Foreign government regulations may define whether products require a public health certificate, and whether additional requirements exist.

The Processed Eggs & Egg Products Export Verification (PEEPEV) Program requires exports to be certified fit for human consumption according to the FDA, up to AMS’ Quality System Assessment (QSA) Program requirements, and meet public health attestations of foreign governments.

Store hard cooked eggs at recommended refrigerated temperatures. Frozen items should be kept at temperatures below 10°F (-12°C). Thaw in the refrigerator and use products as soon as possible after thawing. Value added egg product handling and storage varies by product type and manufacturer.

Be sure to follow specific product instructions from the manufacturer. Keep products at suggested temperatures and use well within expiration dates.

Handling and storage varies by product type and manufacturer. Be sure to follow the manufacturer's specific instructions. Keep products at suggested temperatures and use well within expiration dates. Frozen items should be kept below 10°F (-12°C). Thaw in the refrigerator and use as soon as possible after thawing.

Specialized

Conventional eggs are laid by hens that nest in secure cages with access to feed and water.

Conventional eggs are laid by hens that nest in secure cages with access to feed and water.

Cage free or free range hens lay certified organic eggs. These hens are raised on feed that is grown without most synthetic pesticides, fungicides, herbicides, or fertilizers. One hundred percent of the agricultural ingredients in the feed must be certified organic.

Cage free or free range hens lay certified organic eggs. These hens are raised on feed that is grown without most synthetic pesticides, fungicides, herbicides, or fertilizers. One hundred percent of the agricultural ingredients in the feed must be certified organic.

Cage free eggs are laid by hens that nest indoors in open areas with access to fresh food and water. Some cage free hens may also forage for food naturally outdoors.

Cage free eggs are laid by hens that nest indoors in open areas with access to fresh food and water. Some cage free hens may also forage for food naturally outdoors.

Free range eggs are laid by hens that have access to the outdoors such that factors like weather, environment, and state laws permit. Free range hens are grain fed but may eat wild plants and insects as well.

Free range eggs are laid by hens that have access to the outdoors such that factors like weather, environment, and state laws permit. Free range hens are grain fed but may eat wild plants and insects as well.

These eggs are laid by hens whose feed is modified to produce higher vitamin content in their eggs.

These eggs are laid by hens whose feed is modified to produce higher vitamin content in their eggs.

Omega 3 enriched eggs are produced by hens whose feed has been modified to boost the omega 3 content from the typical 30mg, up to between 100mg and 300mg per egg. Omega 3 eggs can be an excellent source of the essential nutrient that promotes overall cell health in the human body.

Omega 3 enriched eggs are produced by hens whose feed has been modified to boost the omega 3 content from the typical 30mg, up to between 100mg and 300mg per egg. Omega 3 eggs can be an excellent source of the essential nutrient that promotes overall cell health in the human body.

Shell eggs are pasteurized by placing them in moderately warm water for a short period. For effective pasteurization, the water should be warm but not hot enough to cook the eggs. Shell eggs are pasteurized to destroy salmonella and other pathogens.

Shell eggs are pasteurized by placing them in moderately warm water for a short period. For effective pasteurization, the water should be warm but not hot enough to cook the eggs. Shell eggs are pasteurized to destroy salmonella and other pathogens.

Preservation

Egg preservation methods are simple. Properly storing fresh eggs helps maintain their quality and flavor.

Store fresh eggs in their carton with the large end up on an inside shelf of the refrigerator. The carton helps prevent moisture loss and prevents the eggs from picking up odors and flavors from other foods stored in the refrigerator.

Refrigerating eggs is essential. Keep eggs refrigerated between 35°F to 45°F (2°C to 7°C) until they’re used. Never keep fresh eggs outside refrigeration for more than one hour.

USDA requires eggs to be stored at 45°F (7°C) or lower after processing. Recommended long-term storage is 30°F (-1.10°C).

Egg preservation methods are simple. Properly storing fresh eggs helps maintain their quality and flavor. Store fresh eggs in their carton with the large end up on an inside shelf of the refrigerator. The carton helps prevent moisture loss and prevents the eggs from picking up odors and flavors from other foods stored in the refrigerator.

Refrigerating eggs is essential. Keep eggs refrigerated between 35°F to 45°F (2°C to 7°C) until they’re used. Never keep fresh eggs outside refrigeration for more than one hour. USDA requires eggs to be stored at 45°F (7°C) or lower after processing. Recommended long-term storage is 30°F (-1.10°C).

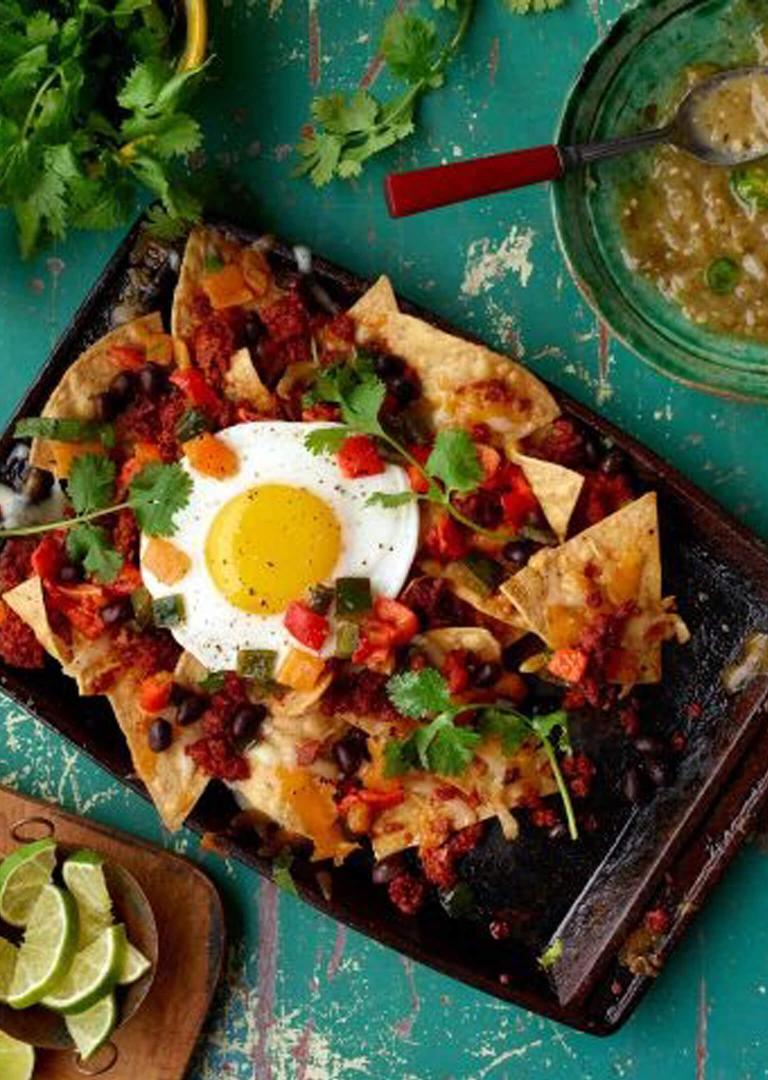

Eggs should be cooked until the whites and yolks are firm. Dishes containing eggs should reach an internal temperature of 165°F (72°C) to destroy salmonella through the heat of cooking.

Eggs should be cooked until the whites and yolks are firm. Dishes containing eggs should reach an internal temperature of 165°F (72°C) to destroy salmonella through the heat of cooking.

America's Egg Farmers ship eggs in refrigerated trucks or aboard ocean vessels in 40 foot (12 meter) refrigerated ocean containers. Ocean container temperatures are typically set at 38°F (3.36°C).

Ocean containers that ship eggs can store the following number of cases per container:

- Extra Large: 756 cases

- Large: 800 cases

- Medium: 880 cases

- Small: 903 cases

Note, the number of cases that can be shipped in a container or truck may be limited due to road weight restrictions in the U.S.

America's Egg Farmers ship eggs in refrigerated trucks or aboard ocean vessels in 40 foot (12 meter) refrigerated ocean containers. Container temperatures are typically set at 38°F (3.36°C).

Ocean containers can store the following number of cases per container:

- Extra Large: 756 cases

- Large: 800 cases

- Medium: 880 cases

- Small: 903 cases

Note, the number of cases that can be shipped in a container or truck may be limited due to road weight restrictions in the U.S.

Egg weights depend on the size of the egg. The minimum net weight per 30 dozen case is as follows:

- Jumbo Eggs: 56 pounds (25.2 kilograms)

- Extra Large Eggs: 50.5 pounds (22.7 kilograms)

- Large Eggs: 45 pounds (20.13 kilograms)

- Medium Eggs: 39.5 pounds (17.8 kilograms)

- Small Eggs: 34 pounds (15.3 kilograms)

Egg weights depend on the size of the egg. The minimum net weight per 30 dozen case is as follows:

- Jumbo Eggs: 56 pounds (25.2 kilograms)

- Extra Large Eggs: 50.5 pounds (22.7 kilograms)

- Large Eggs: 45 pounds (20.13 kilograms)

- Medium Eggs: 39.5 pounds (17.8 kilograms)

- Small Eggs: 34 pounds (15.3 kilograms)

Requests

If this is your first trade lead request, please start by adding your company’s name in our online Trade Lead Request Form. There are not any costs for using the USAPEEC Trade Lead process.

Add the details of your company, contacts and product request specifics.

After your request is submitted, the USAPEEC staff will get to work finding the appropriate supplier for your needs. The supplier will then contact you directly to start the negotiating process.

If this is your first trade lead request, please start by adding your company’s name in our online Trade Lead Request Form. There are not any costs for using the USAPEEC Trade Lead process.

Add the details of your company, contacts and product request specifics.

After your request is submitted, the USAPEEC staff will get to work finding the appropriate supplier for your needs. The supplier will then contact you directly to start the negotiating process.

Welcome back! Please start by searching our database for your company’s name, URL, or email in our online Trade Lead Request Form.

After your company is found, add your product request details and remember to update any company and contact information. Once your request is submitted, the USAPEEC staff will get to work finding the appropriate supplier for your needs. The supplier will then contact you directly.

Welcome back! Please start by searching our database for your company’s name, URL, or email in our online Trade Lead Request Form.

After your company is found, add your product request details and remember to update any company and contact information. Once your request is submitted, the USAPEEC staff will get to work finding the appropriate supplier for your needs. The supplier will then contact you directly.

Request Form Qualify

& Research Product

Request Available Supplier

Contacts You Negotiates

With You Ship

Products

USAPEEC is a trade association supported by U.S. Suppliers with the ability to fast-track your needs at no extra cost.

Please fill out all required fields.

Sustainable for a Growing World

America’s corn farmers have a vested interest in sustainably feeding a growing world. We are doing this not only by working and engaging with our animal agriculture and industry allies, but also with non-traditional partners, like the Environmental Defense Fund.

Since 1980, corn farmers have diligently accomplished numerous achievements: 68 percent decrease in soil loss, 36 percent decrease in greenhouse gas emissions, and 44 percent decrease in required energy to produce a bushel of corn.

Advancements in agricultural technology have assisted the industry in doubling corn yields with less negative externalities on the environment. Corn yields are expected to continue to increase along with projected declines in negative environmental impacts.

America’s corn farmers have a vested interest in sustainably feeding a growing world. Since 1980, corn farmers have diligently accomplished numerous achievements: 68% decrease in soil loss, 36% decrease in greenhouse gas emissions, and 44% decrease in energy required to produce a bushel of corn.

The National Corn Growers Association (NCGA) continues to play a paramount role in the sustainability space, spearheading industry goals and continuously raising the bar for what it means to be a true steward of the land. NCGA is not only engaged with our animal agriculture partners, being a part of the U.S. Roundtable for Sustainable Beef, Dairy Sustainability Alliance, and others, but are also a part of the following initiatives:

- The Soil Health Partnership, celebrating its 5th year, is a network spanning 16 US states focused on research protocols and shared recommendations for farmers to improve productivity and sustainability specific to soil health.

- The Success in Stewardship Network, which launched in February, is a partnership with the Environmental Defense Fund to accelerate conservation practices on corn farms.

- Field to Market is an alliance bringing together supply chain stakeholders to identify opportunities to conserve soil, improve water use, and reduce energy use.

NCGA continues to play a paramount role in the sustainability space, spearheading industry goals and continuously raising the bar for what it means to be a steward of the land. NCGA is engaged with our animal agriculture partners as a part of the U.S. Roundtable for Sustainable Beef, Dairy Sustainability Alliance, as well as other initiatives.

Corn growers and the poultry industry, one of their principal customers, have had a long and mutually beneficial relationship and continue to need each other to remain profitable. Corn and its co-products, such as high protein distillers’ grains, are an excellent, economically efficient way to add valuable nutrient components to the poultry diet, including energy, protein, phosphorus, and xanthophylls.

Corn growers and the poultry industry, one of their principal customers, have had a long and mutually beneficial relationship. Corn and its co-products, such as high protein distillers’ grains, are an excellent, economically efficient way to add valuable nutrient components to the poultry diet, including energy, protein, phosphorus, and xanthophylls.

U.S. poultry consumes over 1.2 billion bushels of the approximately 14 billion bushels of corn produced annually. Through its partnership with USAPEEC, NCGA actively works through our annual carryover stocks by exporting even more corn through poultry year over year as U.S. corn farmers continue their efficiencies and yield gains.

Not only is U.S. corn affordable, sustainable, and abundant, it is also inspected and graded per the USDA Federal Grain Inspection Service Standards. Poultry buyers can rest assured that U.S. corn-fed poultry is top quality.

In the 2019-2020 Harvest Quality Report, 54.6 percent and 81.7 percent of samples met the grade requirements for U.S. No. 1 and U.S. No. 2 corn, respectively. Additionally, 99.4 percent of samples tested below the U.S. FDA action level for aflatoxin and 97.2 percent tested below 5.0 ppb.

Not only is U.S. corn affordable, sustainable, and abundant, it is also inspected and graded per the USDA Federal Grain Inspection Service Standards. Poultry buyers can rest assured that U.S. corn-fed poultry is top quality.

The National Corn Growers Association was founded in 1957 and represents 40,000 dues-paying corn farmers across the nation, as well as the interest of more than 300,000 corn growers who contribute through their states’ checkoff program. With our 50 affiliated state organizations, we work together to create and increase opportunities for corn growers while aspiring to sustainably feed an exponentially growing world.

For more information on the National Corn Growers Association, our programs, and priorities, please visit:

ncga.comThe NCGA was founded in 1957 and represents 40,000 dues-paying corn farmers across the nation, as well as the interest of over 300,000 growers who contribute through their states’ checkoff program.

ncga.com

Commitment to Continuous Improvement

Recognized for its quality, composition, and myriad benefits, U.S. Soy is built on America’s soybean farmers’ commitment to continuous improvement, innovation, and sustainable growing practices. Soybean meal is a high quality option for animal feed. Its protein and range of nutritional benefits make it a popular choice for poultry diets.

Recognized for its quality, composition, and myriad benefits, U.S. Soy is built on America’s soybean farmers’ commitment to continuous improvement, innovation, and sustainable growing practices. Soybean meal is a high quality option for animal feed due to its protein and nutritional benefits.

While U.S. soybean farmers know how much pride they take in protecting both land and water resources, it is even more important to tell that story to the rest of the world. As more customers demand sustainably produced products, it is imperative that soybean farmers evaluate and consider practices that will meet those demands.

In 2015, the United Nations announced 17 Sustainable Development Goals (SDGs) to “provide a shared blueprint for peace and prosperity of people and the planet, now and into the future.” Agriculture plays an important role in addressing the SDGs, and as a global industry, U.S. Soy embraces sustainable agricultural practices, meeting today’s global needs for soy products without compromising the future. In 2019, a soy checkoff-funded initiative mapped the SDGs that connect to U.S. Soy’s priorities by using in-depth stakeholder research to understand U.S. Soy’s potential to contribute to the global UN goals.

More customers demand sustainably produced products, it is imperative that soybean farmers evaluate and consider practices that will meet those demands. In 2015, the UN announced 17 Sustainable Development Goals (SDGs) to follow now and in the future.

The U.S. Soybean Sustainability Assurance Protocol (SSAP) guidelines cover today’s regulatory obligations regarding sustainable practices, but they also call for continuous improvement. Every day, U.S. soybean farmers work harder to be more efficient and environmentally sound. Along those lines, they have established continuous improvement goals for the next five years.

Based on benchmarks from 2000, by 2025, U.S. soybean producers aim to:

- Reduce land-use impact by 10% (land area per unit of production, hectares per metric ton of acres per bushel).

- Reduce soil erosion by an additional 25% (land area per unit of production, tons per bushel).

- Increase energy-use efficiency by 10% (energy unit per unit of production, joules or BTUs per bushel).

- Reduce total greenhouse gas emissions by 10% (units of gasses emitted per year, kilograms or pounds of CO2 &mdash equivalent gasses emitted per year).

The U.S. Soybean Sustainability Assurance Protocol (SSAP) guidelines cover obligations regarding sustainable practices. U.S. soybean producers aim to: Reduce land-use impact by 10%, reduce soil erosion by an additional 25%, increase energy-use efficiency by 10%, and reduce greenhouse gas emissions by 10%.

U.S. soybean meal’s high quality composition has long been prized by feed manufacturers and formulators. All quality indicators of soybean meal, such as crude protein, crude fiber, neutral detergent fiber, sugars, and amino acid profiles, should be taken into account by purchasers to determine the meal’s true value. Recently, a meta-analysis looked at 18 different studies and 1,944 samples of soybeans from Argentina, Brazil, India, and the United States to quantify the relationship between the country of origin and the chemical composition, protein quality, and nutritive value of the resulting soybean meal. The data from this study were then processed by the Nutrient Value Calculator (NVC), a software tool constructed by Genesis Feed Technologies. This cost analysis supported the economic benefits of U.S. soybean meal relative to meal from other origins as a key ingredient in poultry rations.

U.S. soybean meal’s high quality composition has been prized by feed manufacturers/formulators. Quality indicators of soybean meal, such as crude protein, crude fiber, neutral detergent fiber, sugars, and amino acid profiles, should be taken into account to determine the meal’s true value.

The United Soybean Board’s 78 volunteer farmer-directors work on behalf of all U.S. soybean farmers to achieve maximum value for their soy checkoff investments. These volunteers invest and leverage checkoff funds in programs and partnerships to drive soybean innovation beyond the bushel and increase preference for U.S. Soy. That preference is based on U.S. soybean meal and oil quality and the sustainability of U.S. soybean farmers. As stipulated in the federal Soybean Promotion, Research and Consumer Information Act, the USDA Agricultural Marketing Service has oversight responsibilities for USB and the soy checkoff.

For more information on the United Soybean Board, visit:

unitedsoybean.orgThe United Soybean Board’s 78 volunteer farmer-directors work on behalf of all U.S. soybean farmers to achieve maximum value for their soy checkoff investments. For more information, visit:

unitedsoybean.org